Handmade velvets are the most exclusive fabrics in our production. In addition to the 3,500 designs kept in our historical archive, we can create new ones at customers’ request. Custom handmade velvets represent the ultimate in exclusivity, ideal for both furnishings and high fashion. We have made many of them, and in this article, we want to tell you how a custom soprarizzo velvet is created, taking the precious Giardino Fioroni as an example.

Fioroni Soprarizzo: The Opulence of a “Giardino” Velvet

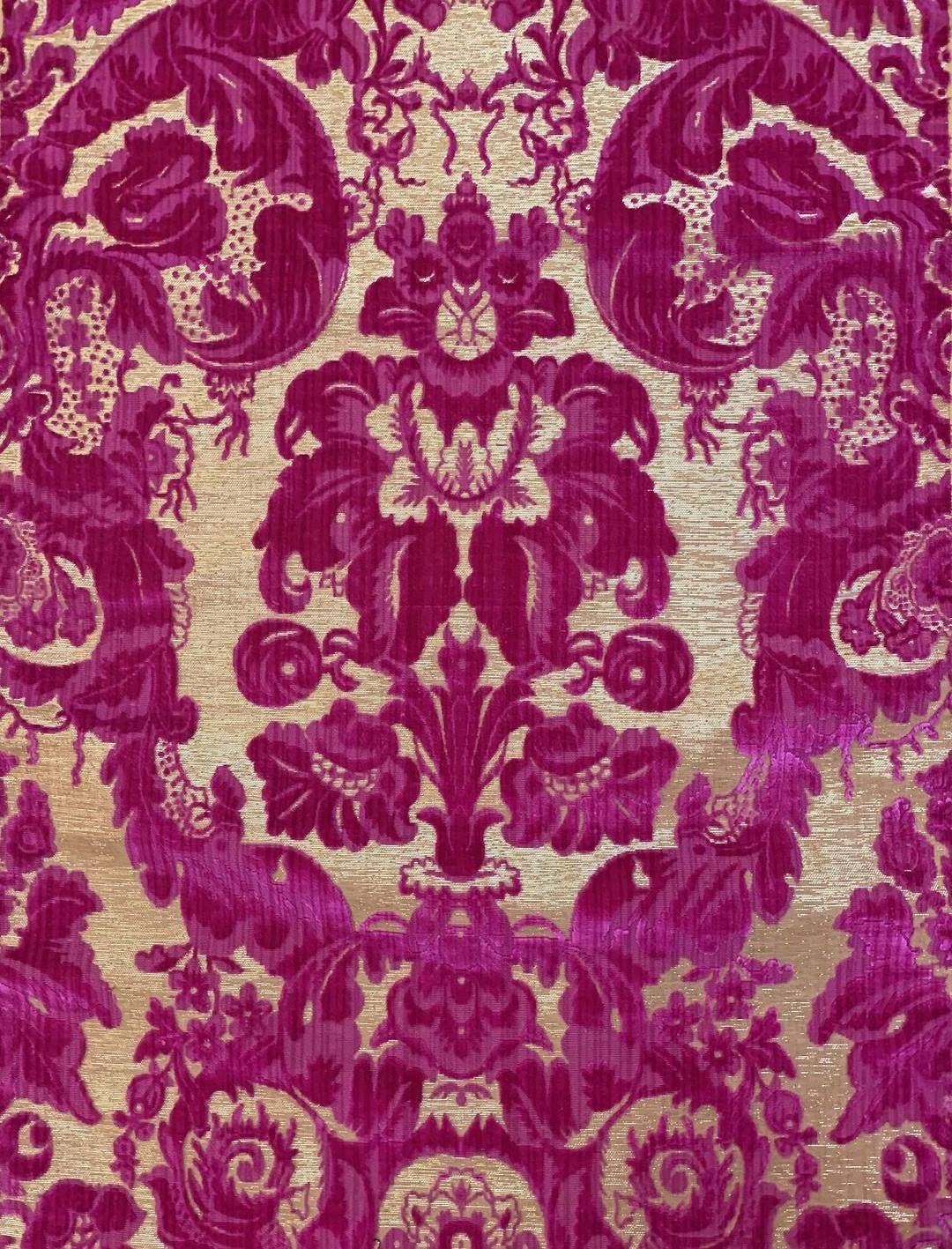

If soprarizzo is the king of velvets, the so-called “Giardino” or “jardiniere” velvet is its maximum expression. The richness of details and colors makes it one of the most beautiful and exclusive velvets to own. An example of such beauty is the silk soprarizzo Giardino Fioroni, created by our Tessitura.

The pattern of the Giardino Fioroni soprarizzo velvet is inspired by the French and Italian velvets of the second half of the 17th century. The variety of plants and flowers depicted, with deliberately exaggerated and full-bodied volumes – as well as their placement – are typical of the Baroque period.

Thick twisted and curling plant stems with leaves, shoots, ornamental beads, and coral encrustations stand out against a light background. From them, twigs of roses, bellflowers, and jasmine climb up, creating a frame within which a floral composition of parrot tulips, rosebuds, a large peony, and a bouquet of bindweed triumphs.

Due to the special processing of the soprarizzo, described in this article, the velvet appears visually darker or lighter depending on the incidence of light, creating a three-dimensional effect and different shades of color.

The color variants currently available are light blue, fuchsia, green, multicolor ash, multicolor green, and dusty blue-brown. However, it is possible to customize it, by studying new color combinations with our team to make your own Giardino Fioroni velvet even more unique and exclusive.

Drawing Jacquard Velvets: The Requirements of Handlooms

Not all patterns can be reproduced by a Jacquard loom like those we use in our Venice workshop. Our technical director, Emanuele Bevilacqua, a master of art and designer, knows these tools inside out, and he is the one in charge of adapting each design to turn it into a wonderful silk velvet.

Because of the specifics of the looms and handwork, the number of colors required and the complexity of the design must be carefully considered. To respect the original idea, the pattern is designed together with the customer, following the loom rules, which imply:

- creating a repeatable pattern along the length of the fabric. In fact, looms work by reproducing the same decorative module cyclically;

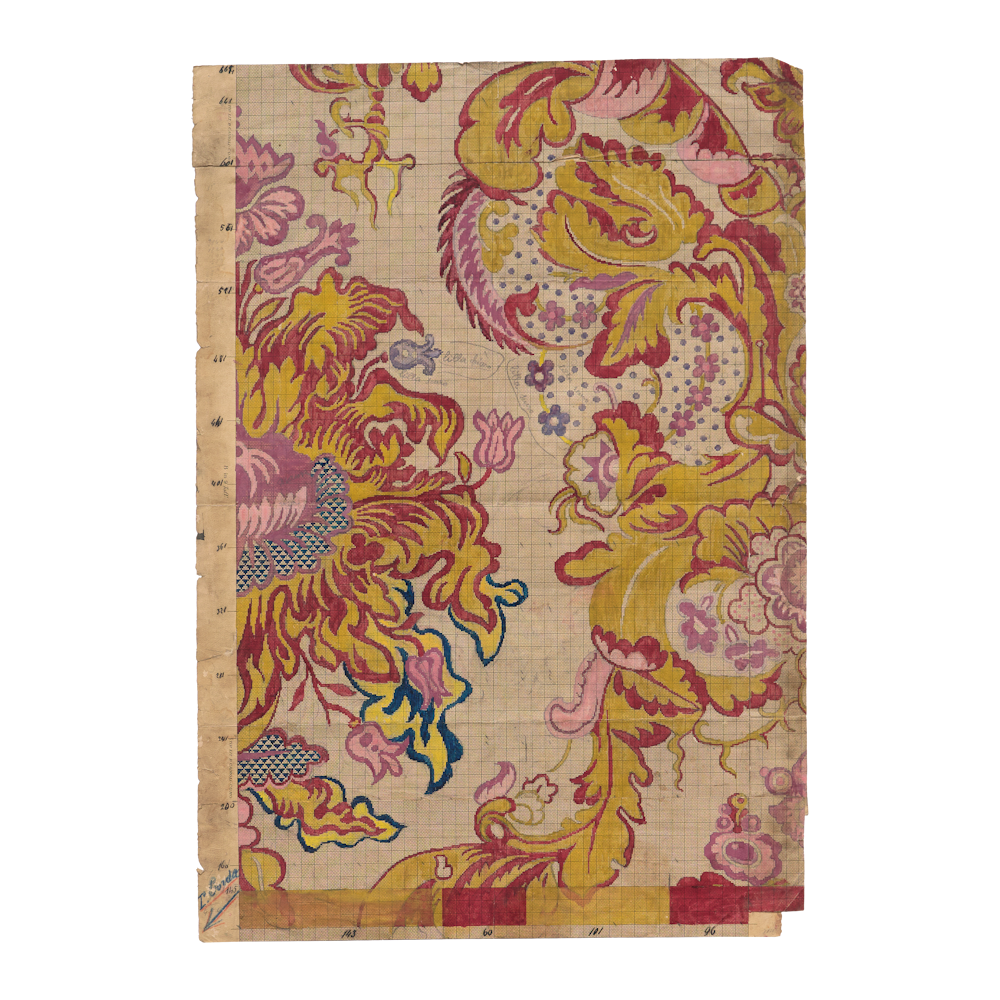

- drawing the pattern on graph paper, which will serve as the basis for transforming the design into operational information for the loom, i.e., the holes on the punched cards used by the Jacquard machine to make the decoration;

- reducing, if necessary, the number of colors: thanks to our experience, we can maintain the chromatic richness of the original design even with a reduced palette. This is possible because, as we saw earlier, cut velvet, which reflects light and appears lighter, and curly velvet, which absorbs it, resulting in darker colors, coexist in the same fabric. Thus, each yarn can return multiple shades of color.

Giardino Fioroni Soprarizzo Velvet – Technical Drawings on Graph Paper

The person who creates the pattern of a handwoven velvet, already knows what shades it will take on once woven. Only with this knowledge is it possible to properly design the punched cards that will guide the weavers’ work. A clear design allows them to arrange the spools of the right color on the loom and proceed with weaving.

Therefore, the manual production of a velvet is a choral work that requires time and expertise, right from the initial design stage.

Making of the Giardino Fioroni Soprarizzo Velvet in Dusty Blue-Brown

Projects with Giardino Fioroni soprarizzo velvet

This silk velvet is still today rigorously hand-made with a complex, slow, and patient process (the daily production does not exceed 30 cm!) and takes shape on original 18th-century wooden looms. It has been chosen for many prestigious projects. Among these, its use to cover the columns of the Cathedral of Caorle during the most solemn celebrations stands out.