An emblem of power and wealth, velvet has been the fabric of choice for popes and nobles for centuries. The word “velvet” comes from the late Latin “vĭllūtus,” a derivative of “villus,” meaning “fur” of fur-bearing animals. In modern times, luxurious velvet is appreciated not only by major fashion brands but also by interior designers and home decorators.

Soprarizzo (also called “soprariccio”) or cesellato velvet, in particular, is the most precious of our manually produced velvets. That’s because it’s woven on original 18th-century looms and requires a more complex manufacturing process combining cut and curly velvet. The result is a unique fabric with silky, brilliant tones, and a three-dimensional design.

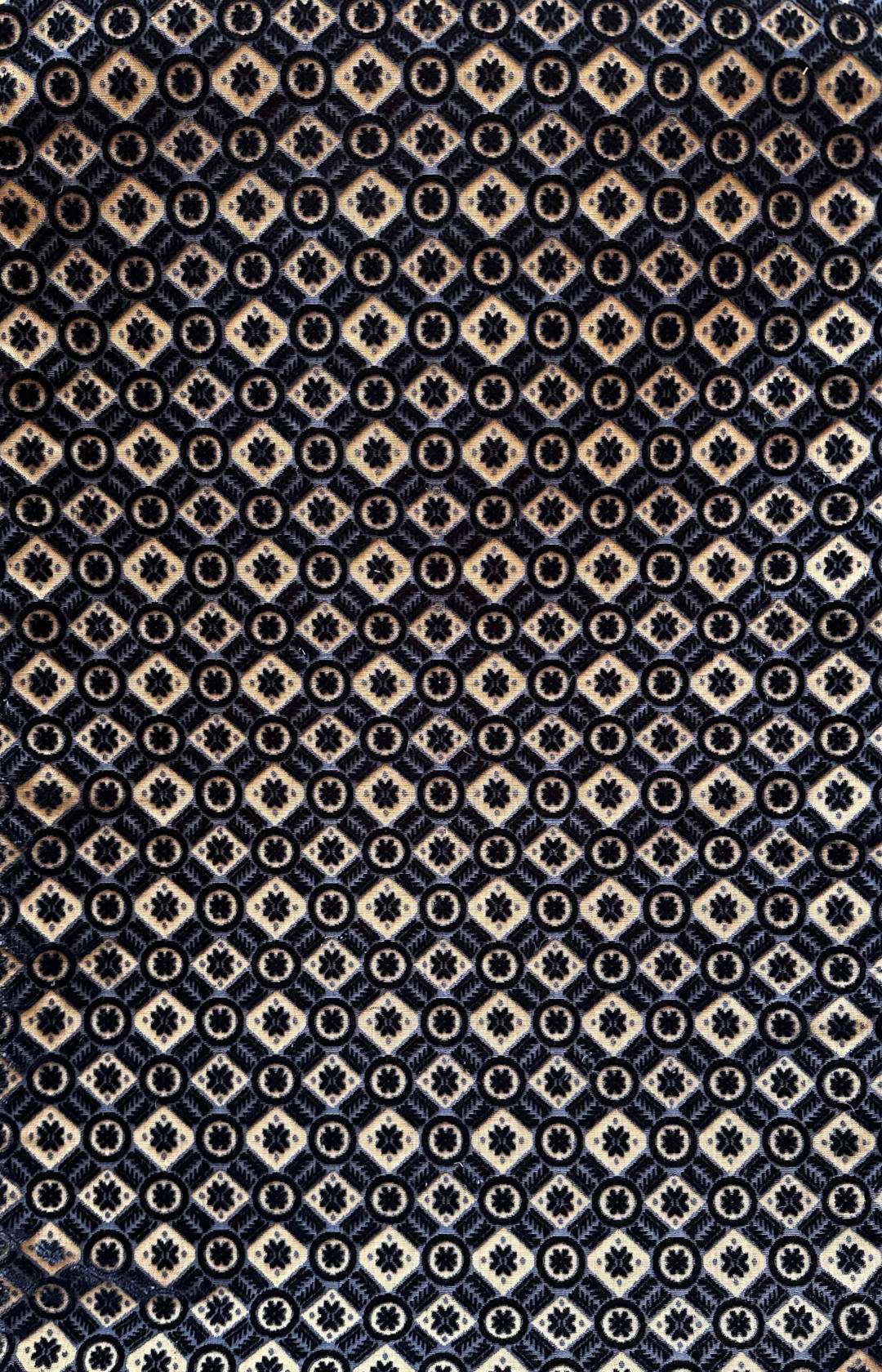

Giardino Fioroni Soprarizzo Velvet – Tessitura Luigi Bevilacqua

The Characteristics of Our Soprarizzo or Cesellato Velvet

Certain features make this precious fabric incomparable, helping us to recognize it.

- Each cesellato velvet is a unique piece and an exclusive creation of the highest craftsmanship. In fact, despite weavers’ excellent skills, the pressure they apply to the loom in the weaving process, which is entirely manual, can vary slightly from day to day.

- Traditionally, the pile of the soprarizzo velvet is made exclusively of pure silk. Using silk gives soprarizzo velvet fundamental qualities. Luster and color brilliance, because of the way silk reflects light and keeps colors vibrant over time. Softness, because silk has a very soft and slippery hand, which makes the fabric extremely pleasant to the touch. Elegance, because the drape of silk is fluid and refined.

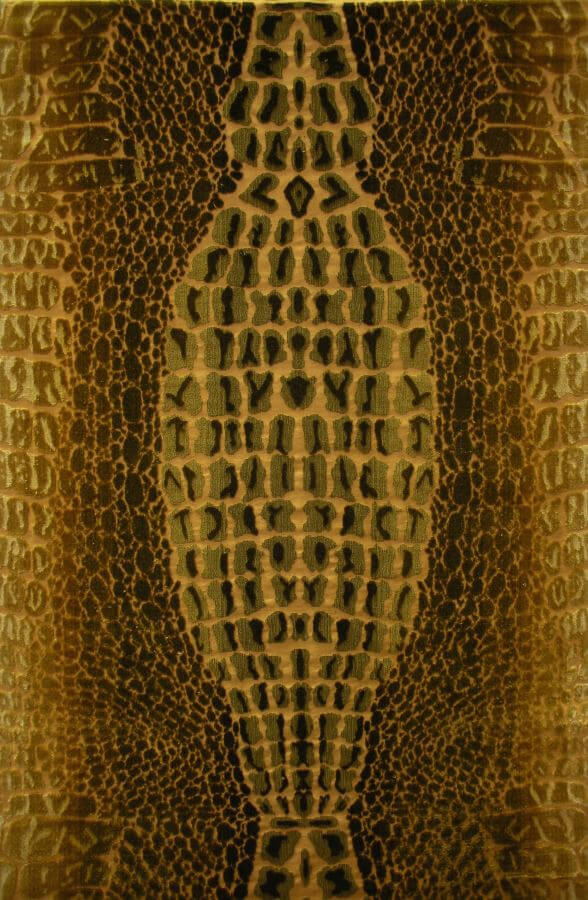

- It’s an iridescent fabric, thanks to the presence of two different types of pile, one curly at the base and one cut, smoother and higher. This process enhances the design with its three-dimensionality and, above all, allows light to reflect differently on the two types of velvet, making the cut pile darker and the curly one lighter, thus creating extraordinary effects of light, shade, and depth.

- The manual velvet process is so complex that it requires weavers with a great deal of training and experience: it takes years to master this art.

- Daily production is only about 30 cm. This is because its processing is very complex and time consuming and requires, among other elements, precision and physical strength. Our weaver must press the loom pedals to move both the perforated cards in the Jacquard machine and the warp and weft threads. In addition, for each millimeter of fabric, she must pull out the iron bar that creates the curly velvet and slide the blade over the one that makes the cut pile. Moreover, the 18th-century loom isn’t as fast as modern machines and often needs to be recharged and reset.

- The width of this fabric does not exceed 67 cm (which corresponds roughly to the length of an arm). This is for a practical reason: in producing manual velvet, the weaver must continuously cut the silk threads that form the pile across the width of the fabric with a sharp arm movement. If the fabric were wider than her arm span, the cut wouldn’t be clean and precise.

- The preparation of the manual loom can take up to 6 months and requires from two to three of our weavers. It begins with a drawing that is reproduced on graph paper to create the punched cards that are the basis for the functioning of the jacquard loom. Next, the warp is prepared on original 18th-century revolving warpers, and the cantra is set up. The cantra is the machine used to load the threads on the loom, where our weavers patiently place hundreds of reels of thread.

These are just some of the characteristics that make cesellato velvets not only a product of extraordinary beauty but also of great artistic and craft value. Like the furnishings made from them, such as decorative cushions, cesellato velvets are unique and precious artifacts because they express centuries of tradition and art and represent a knowledge passed down by a select few weavers worldwide.

Cover Photo Credit: Elena Rosignoli